Methodology Development and Validation of Weight Optimized Stiffeners Run-Out Design for Future Composite Wings

Date

Brief overview

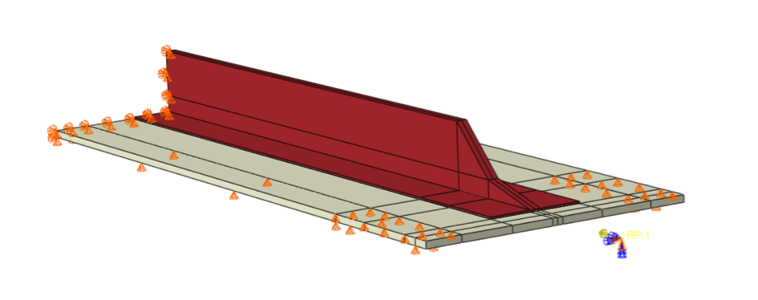

DOVER has aimed to develop a design optimization tool and methodology dedicated to supporting the design of innovative, weight-optimized stiffened composite panel configurations, with the ability to improve all areas and configuration parameters, such as geometries, stacking sequences, and anti-peeling rivets. The accuracy and reliability of the resulting methodology have been validated through experimental testing.

DOVER's proposed solution has been the creation and validation of a design tool and methodology that enables the optimization of structural composite stiffened panels for wings. The developed tool provides an environment for researching innovative lightweight designs, including reinforcement geometry, the thickness and arrangement of different components, the shape of the taper, and the configuration of anti-peeling rivets. Using this tool, the designer can predict the failure of any stiffener run-out configuration and achieve overall panel optimization with considerable time savings, as it does not require complex numerical models to predict behavior, and cost savings, as it eliminates the need for expensive testing campaigns.

To achieve this solution, DOVER has structured the process in different stages to ensure maximum quality, precision, and reliability. An initial experimental study of the stiffened panel's behavior establishes an experimental foundation used to develop a model and generate a methodology for predicting failure. This methodology is then implemented through the design of various innovative stiffened panel configurations. The optimized solutions are evaluated and correlated with the experimental results. Finally, in a final stage, single-stiffened panels are manufactured, and stresses and deformations at the point of failure are measured to validate the development.

The work carried out to achieve the aforementioned objectives has been structured into four main tasks:

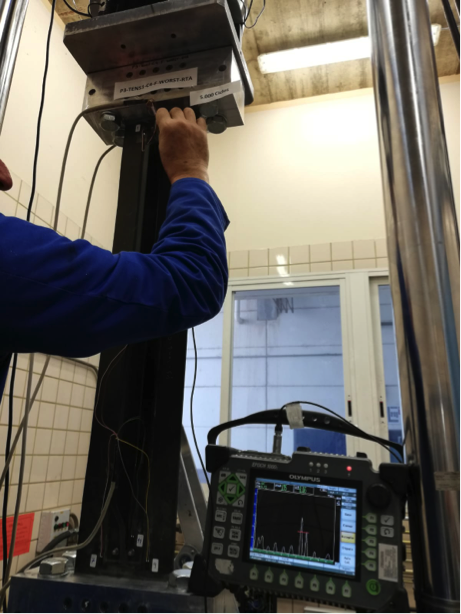

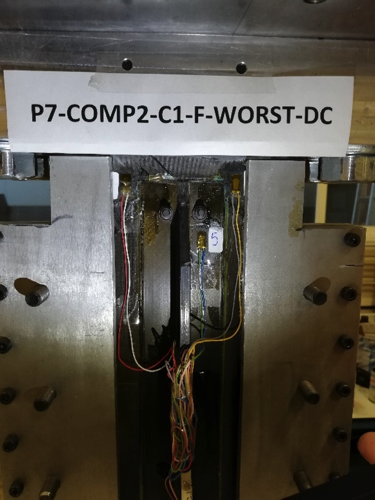

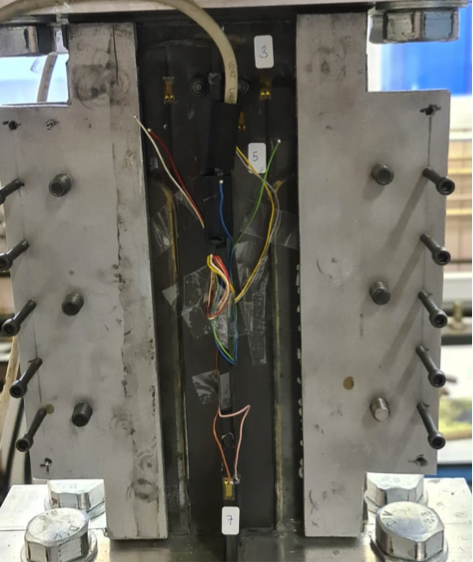

Task 1.- Definition of the testing campaigns, manufacture of test specimens and execution of the initial testing campaigns, including impact on test specimens, tensile and compression tests, both static and fatigue after impact and carrying out these tests at ambient temperature, in cold conditions and in humid and hot conditions.

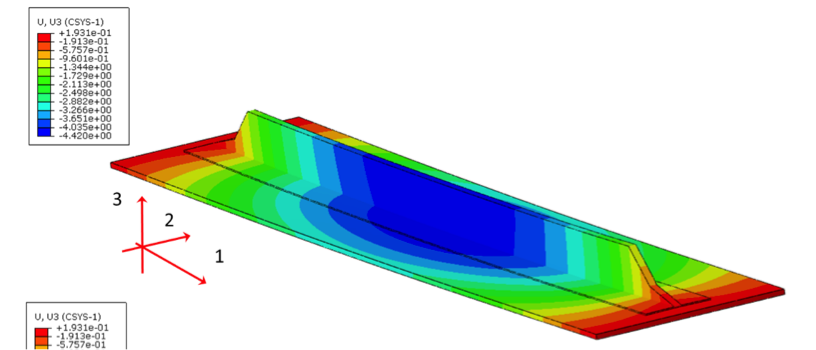

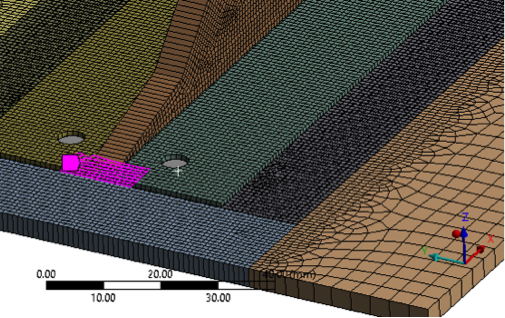

Task 2.- Development of finite element models, correlating their results with the results obtained experimentally for the subsequent development of a methodology and a criterion that allows predicting the onset of failure.

Task 3.- Development of innovative stiffened panels through optimization strategies in simple finite element models using the project methodology.

Task 4.- Validation of the new designs through experimental tests on mono-stiffened specimens under tension and compression with both static loads and fatigue after impact.